>OPV Structure-Function Research

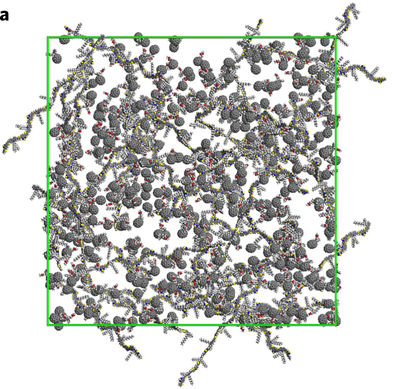

Organic photovoltaics (OPVs) have recently gained popularity among condensed matter researchers due to rapidly increasing power conversion efficiencies with newly discovered materials as well as the ease of fabrication inherent with the technology. These devices, which are created using a blend of an electron donor material and an electron acceptor material, consist of a thin film photo-active layer that are ideally deposited on a substrate through high-throughput printing techniques such as roll-to-roll coating. However, obtaining a thin film which has a structure that optimizes the electrical properties of the device is difficult and depends upon many different factors, including material type, fabrication technique, substrate choice and many others. Our group is interested in untangling these relationships by investigating the phenomenological structure-function relations using Grazing Incidence Wide Angle X-ray Scattering (GIWAXS), Resonant Soft X-ray Scattering (R-SoXS) and Polarized Soft X-ray Scattering (P-SoXS) to probe the morphology of the thin film under various conditions.

Ye, et al. Nature Materials, 2018, doi:10.1038/s41563-017-0005-1

>Thermodynamics

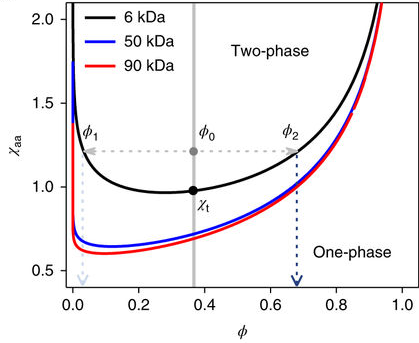

Currently, most OPV research consists of “post-mortem” device characterization and requires extensive trial and error. This approach is extremely labor-intensive and does not result a predictive model. One area of research that our group is pursuing is the use of model systems to understand the thermodynamics of mixing as described by the Flory-Huggins model of polymer solutions and how it relates to device performance. To accomplish this feat, we use Differential Scanning Calorimetry (DSC), Scanning Transmission X-ray Microscopy (STXM) and Secondary Ion Mass Spectroscopy (SIMS) on our model systems to determine the Flory Huggins interaction parameter (χ) and relate it to device performance. The goal of this research is to determine a relationship between χ and device performance so that new materials can be screened for good performance by measuring χ instead of trial and error device fabrication.

Ye, et al. Nature Materials, 2018, doi:10.1038/s41563-017-0005-1

>Scalable and Green Fabrication Techniques

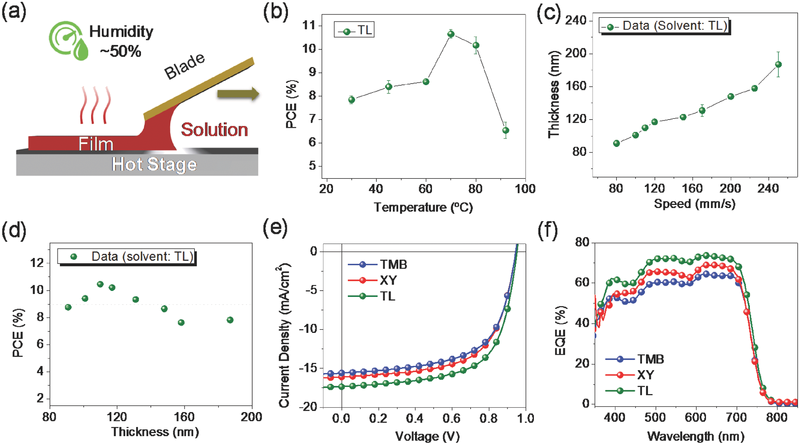

In order for OPV to be viable for consumer products, scalable fabrication techniques coupled with high efficiency must be achieved. Current industrial fabrication methods such as roll-to-roll coating, slot-die casting and blade coating lead to inferior film morphology compared to laboratory preparation (often by spin-coating, a non-scalable technique). This inferior morphology leads to reduced device performance and dampens industry interest in the technology. Not only that, but most fabrication techniques utilize halogenated solvents which pose an environmental risk. To address these issues, our group has engaged in device optimization using scalable fabrication techniques in conjunction with green solvents. In addition, we are investigating alternative device architecture such as sequentially-cast binary devices and ternary devices that could supplement the inferior morphology resulting from scalable fabrication techniques.

Ye et al. Adv. Materials, 2018, doi: 10.1002/adma.201705485

>OFETs

Another aspect of organic electronics our group is engaged in is the development of Organic Field Effect Transistors (OFETs). OFETs have gained much attention recently due to their ease of fabrication as well as their application in flexible electronics and bioelectronics. These devices use an organic polymer semiconductor rather than a traditional crystalline semiconductor to form the transistor channel, and it is how the polymer crystalizes in the film that determines how the carriers behave in the channel. To probe the polymer structure, we primarily utilize GIWAXS in order to understand the relationship between morphology and OFET electrical characteristics such as electron/hole mobility and threshold voltage. The goal is to use OFETs as a tool to understand the structure-function relationships in organic thin films.

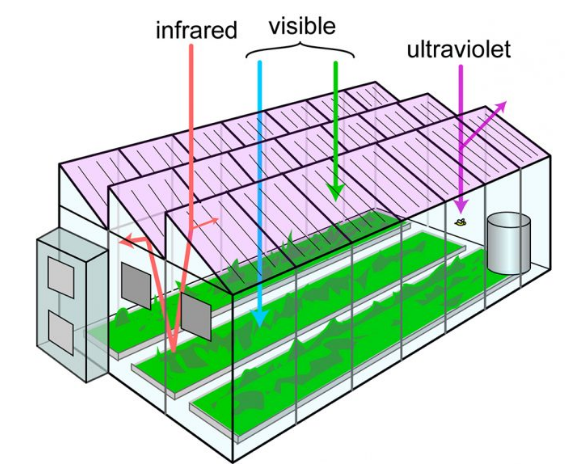

>Integrated Technology

The integration of OPV technology with other fields, such as agriculture, is a long-term goal of our group and one that we have ongoing research in. The prime example of this would be our Solar Powered Integrated Greenhouse (SPRING) project, which attempts to combine solar power generation with a self-contained greenhouse environment. By tuning the composition of the transparent solar cells, we can prevent overlap of the cell absorption spectrum and the plant absorption spectrum, therefore utilizing all of the solar spectrum in both power generation and plant growth. By utilizing the power generated by the solar cells to maintain optimal temperature and humidity, we can increase the efficiency of the greenhouse to the point of self-sustainability.